Furthering its commitment to the performance industry and its loyal customers, HPA has invested in an AWD Superflow chassis dyno. The introduction of this state-of-the-art testing hardware to our facility links our product development team with a medium for expedited software and durability evaluation. With this world-class chassis dyno at our disposal, our team will set to work fine-tuning the expectations in performance and durability that our customers will come to demand from the aftermarket.

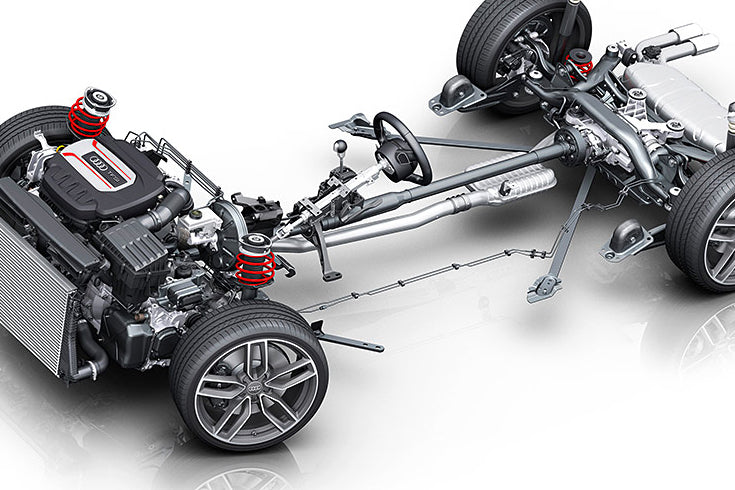

Superflow’s Autodyn 30 is a dual-purpose dynamometer. Featuring an industry-standard inertia mode, wide-open throttle horsepower pulls are generated with unmatched repeatability. For furthering HPA’s DSG and turbo development, the Autodyn 30’s Eddy Current Brake assembly will facilitate long steady-state durability runs allowing our engineers and product team to test any user condition at the flick of a switch. Superflow stands at the top of its industry with both rollers connected through a drive shaft to avoid any ESP and ABS sync issues commonly found when testing today’s technical AWD platforms.

SuperFlow® does not use complicated belt systems that stretch and break or inconsistent electronically synced systems that allow the front and rear rollers to spin at different speeds, causing driveline windup and damaging driveline components. Differentials and driveshafts allow SuperFlow® to measure and compensate for the parasitic losses of every dyno produced so that each one leaves the factory calibrated with its own inertia and parasitic data. The end result is the most accurate torque and power measurement available. Further, torque is measured using two temperature-compensated load cells, one at each roll set, so you can see total torque across the rpm range, but also the torque split between the front and rear axles.

The 30” knurled rolls provide superior traction and minimal tire deflection, so testing is accurate and repeatable. It combines the low-profile frame commonly found on cradle roll systems with the added traction benefits of a large single-roll dyno, so it works perfectly in a pit with a 4-post lift. It features push-button wheel base adjustment so it easily accommodates most AWD vehicles on the road today.

Primarily used for HPA in-house development projects, private dyno time is occasionally available by appointment.